PU – 50 (Heavy Duty PU Waterproof Coating)

PRODUCT DESCRIPTION

Chemistik PU – 50 has been specially developed from latest PU Technology which is eco friendly to provide heavy duty waterproofing with long term durability. It is one component coating ideally suited for concrete waterproofing of new and remedial work which is not directly exposed.

APPLICATIONS

Suitable for all types of new and maintenance works. Highly recommended for waterproofing of concrete such as all types of roofs, flat or sloping or domes, Bathrooms, kitchens, balconies, etc. which needs to be protected with screed or concrete. All types of underground structures like basements, subways, channels, bridge foundations, tunnels, aqueducts, etc. Also recommended for protection of concrete in tanks used for storage of wastes and effluence like sewage, seawater, molasses, effluence containing acids or alkalis, cooling towers and all types of unexposed metal structures in heavy Industries like Chemicals, Steel, Power, etc.

METHOD OF APPLICATION

No primer required unless otherwise recommended for areas which cannot be prepared. Stir thoroughly before use. CHEMISTIK PU – 50 can be applied by brush or roller squeeze blade or airless spray equipment. Apply first coat on prepared surface. Apply second coat within 6 – 8hours at right angle to the first coat. Inter coating interval should not be more than 10 – 12 hours.

Finishing PU – 50 should simultaneously be applied to all openings, protrusions, outlets, parapet walls, copings, gutter valleys and expansions joints, forming a good seamless watertight finish. Treated surface should be allowed to cure for minimum 96 hours at ambient temperatures of 30°C cooler temperatures the cure time will increase accordingly.

STORAGE

Store in cool dry place away from direct sunlight. Shelf life 6 – 8 months in Original Containers.

PACKING

25 Kgs. Drums

STANDARDS

ASTM C 836

ADVANTAGES

- High Build Coating hence longer durability

- Crack bridging properties up to 1 – 2 mm.

- Good for horizontal or vertical surfaces

- Easy to use, one component

- Very strong bond with concrete/metals

- Can withstand temperature variations

- Will not crack or peel. High elongation

- Resistant to oil, mild acids, alkalies

- Seamless Coating

PREPARATION

Clean all foreign matter such as dirt, dust, grease, laitance, motar dropping, loose and flaking materials. Algae and fungus must be removed using suitable fungicide solution or bleach or dilute HCL solution, thereafter wash and rinse thoroughly. Necessary repairs to defects must be carried out prior to coating like crazed, unstable or hollow surfaces, major cracks, any protrusions, outlets, construction joints, etc. For cracks and joints, use our CHEMISTIK PU 25 Sealant. All surfaces to be treated must be properly prepared, sound clean, dry and fully cured and ready. New concrete to be cured thoroughly for 28 days prior to coating. For coating on metals, please consult our engineers for preparation of surface and suitable primer to be applied.

CLEANING OF TOOLS

It is recommended to use protective gear whilst working like gloves, goggles, etc. All tools equipments etc. to clean with solvent like Xylene, Toulene, etc

PRECAUTIONS

Do not mix anything in the material or it will be useless. Work in well ventilated areas and do not smoke during application. Keep away open flames, lights, etc.. Do not work when humidity is very high and temperatures should not be less than 5°C and more than 45°C. Avoid working during afternoons when temperatures are maximum. Do not apply during inclement weather or when rain appears imminent. Coverage may vary from surface to surface, it is advisable to carry out a test sample. Do not apply more than 0.5 mm thickness per coat.

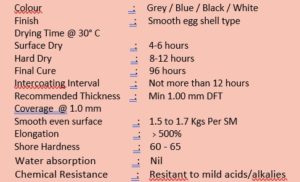

PRODUCT DATA

PU 50