PMC – 500 (Polymer Modified Coating)

PRODUCT DESCRIPTION

CHEMISTIK PMC-500 is a Two component Polymer Modified Cementitious Coating. It is supplied in preweighted packs. This grey coloured membrane coating is a flexible water proof barrier. It prevents ingress of water on most masonry surfaces including concrete water retaining structures.

APPLICATIONS

- All kinds of Roof Slabs, Cobas as a sandwich coat.

- Portable Water Tanks.

- Toilet Sunken Slabs. Kithcen areas.

- As a backing to Marble & Granite to prevent ingress of Water.

- For fixing tiles.

- Protection against salt petre and rising dampness in walls.

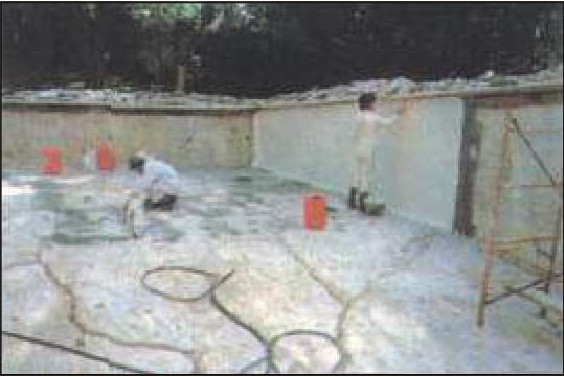

METHOD OF APPLICATION

The prepared surface should be dampened with clean water. Care should be taken to remove excessive water or any standing water. The mixed material can now be applied by a stiff bristle brush achieving a minimum DFT of 200 microns per coat, ensuring that mix material is applied immediately as it has a limited pot life, finishing in one direction only, and allow to dry for minimum 2-3 hours at ambient temperatures of 30 °C. Subsequent or second coat, should be applied as soon as 1st coat is set hard depending on the problems or anticipated water pressure and type of structure being treated. Consult our technical engineer for guidance.

PRECAUTIONS

- Proper protection must be taken during application, to avoid direct contact with skin and eyes and inhalation of dust during mixing, to protect wear gloves, googles & dust mask.

- Do not commence application when rain is imminent or do not apply when temperatures are below 5°C or on standing water or excessively wet areas.

- Avoid splitting the pre weighted packs supplied or adding any other materials as this will directly affect the quality of the product.

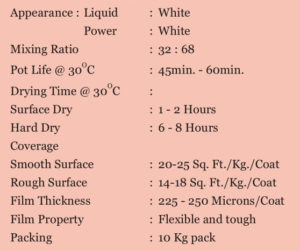

Also available in White for exposed treatment:

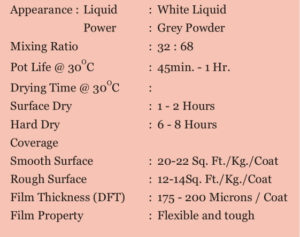

PRODUCT DATA

PMC WHITE

ADVANTAGES

- Easy to use by brush trowel or spray/one coat system.

- Excellent bond to Masonry/Concrete surfaces.

- Excellent crack bridging properties.

- Can be applied on Green/Damp Concrete.

- Provides good anti-carbonation cover.

- High weathering resistance.

PREPARATION

Surface preparation is of prime importance. The surface must be clean, completely free from loose dirt, mortar droppings, grease, oils etc. and most important the surface must be firm. Loose, hollow or broken areas must be repaired with cement mortar. Bulk mixing should be done in another container by pouring the liquid first, thereafter the powder to be added slowly under stirring conditions. The mixing should continue until the mix is lump free for a minimum of 5 minutes and not for too long. For bigger packs a slow electric stirrer should be used for proper mixing as by hand it would be very difficult.

PACKING

Available in 3 Kgs., 16 Kgs.

CLEANING OF TOOLS

Clean hands tools with water immediately, any hardened material in the area can be removed by spatula, scrapper, etc.

STORAGE

Store in a cool, dry place, away from direct sunlight.

PRODUCT DATA

PMC - 500