PU – 2000 SL (Self Levelling Polyurethane)

PRODUCT DESCRIPTION

Chemistik PU – 2000 SL is a self levelling polyurethane based floor screed designed for use at thickness ranging from 2 mm – 5 mm. It consists of mineral aggregates together with pigmented polyurethane resin suitable for floors where high abrasion and impact resistance along with chemical resistance is required This thermal shock proof system is also suitable for use in wet process conditions and where bacteria cannot be tolerated. It provides a quality, cost effective alternative to tiling.

APPLICATIONS

This PU system is suitable for floors in many environments such as in food processing factories, abattoirs, drink and beverage industries, dairies, pharmaceutical industries , cold storages, meat processing factories etc. In fact all such areas where ftmgus or growth of bacteria cannot be tolerated. Also in areas like Hotel kitchens, health clubs, Hospitals, operation theatres and many such fields of application.

METHOD OF APPLICATION

All materials are two and three component where thorough mixing in right proportions as instructed must be followed. On prepared surface apply one primer coat of Chemistik EP – Seal 100. Two component solvent base primer to the surface. Very porous surfaces may need a second coat of primer. In a separate mixing vessel with aid of slow stirrer mix the resin hardner and aggregates as supplied until a uniform homogenous mix is attained then pour and spread with notched trowel as per the thickness required, after which use a spiked roller to remove any entrapped air bubbles. In colder temperatures spiked may be required twice. To avoid shade variation it is important to monitor the mixing and laying time which should be within the same time frame at every time. Due to limited pot life use material immediately. Light traffic can be allowed within 24 hours.

PRECAUTIONS

Work in well ventilated areas. Use protection for eyes hand and face, avoid direct inhalation and contact with skin • mixed material to be used immediately • Do not smoke in the area and keep away from open flames or naked lights • Do not split packs.

STORAGE

Store in a cool dry place away from direct Sunlight.

PACKING

20 Kgs. Pack

ADVANTAGES

⦁ Economical than tiling

⦁ Fast cure minimizes down time.

⦁ High abrasion and impact resistance.

⦁ Low modulus – hence resistant to thermal shock.

⦁ Excellent resistance to many chemicals.

⦁ Slip resistant-including in wet areas.

⦁ Seamless no joint failures.

⦁ Antifungal prevents growth of bacteria.

⦁ Easy to clean and low on maintenance.

⦁ Can accommodate wide temperature fluctuation.

PREPARATION

Chemistik PU – 2000 SL system is suitable for new as well as old concrete floors. All new concrete floors must be cured for 28 days prior to treatment. Long term durability of floor systems depends on the bond achieved between the system and floor. Therefore it is very important that the surface is meticulously prepared prior to laying the system. Check whether excessive moisture is present in the floor. Check for any undulations damaged or spalled concrete, repair the same with Chemistik Rapid setting mortar. Thereafter clean the surface from loose dirt, dust, oil, grease, mortar droppings, laitance previous coatings any foreign material. Mechanical cleaning is recommended for large areas after thorough washing cleaning allow to dry.

CLEANING OF TOOLS

Clean hands, tools etc. with EP – Thin 200. The use of gloves, goggles and barrier creams is recommended.

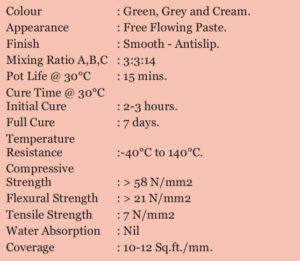

PRODUCT DATA

PU - 2000 SL