SB – 65 (Superior Masonry Coating)

PRODUCT DESCRIPTION

SB – 65 is a superior High Build Coating based on acrylic combined with premium resins, pigments, fillers and solvents. Its excellent water resistance not only water proofs the surface but also weather proofs and decorates the surface for years to come.

APPLICATIONS

Ideally suited for external applications on plaster, brick, blocks, rough cast slabs, pebble dash plasters. It can be used on new as well as painted surfaces for remedial work.

METHOD OF APPLICATION

Always stir the contents well before use. New surfaces and highly porous surfaces need to be primed with our Primer AC-10 and allowed to dry for 3-4 hours.

SB – 65 can be applied by brush, spray or rollers.

Apply first coat on primed surface to old painted surface but prepared as above moving the brush / spray / roller in one direction. Allow to dry for 8 – 10 hours.

Apply second coat moving at right angles to the first coat.

Any further subsequent coating is recommended to be applied at intervals of 8 – 10 hours between each coat.

PRECAUTIONS

Work in well ventilated areas and do not smoke during application and away from open flames, lights etc. Application should not commence during inclement weather or when rain appears imminent. On extremely hot days it may be necessary to dampen the surface before application.

PACKING

4, 20 litres.

CLEANING OF TOOLS

Wash hands, tools with mineral turpentine.

STORAGE

Store in a cool, dry place away from direct sunlight.

ADVANTAGES

- Flexibility: Its high elasticity can withstand the temperature variations including normal expansion / contraction of buildings. Hence will not crack, peel or spall.

- High Build: Its high build will hide all hairline cracks and preserve the architectural features of the building besides protecting the structure from deterioration through atmospheric pollution.

- Breathability: It creates a waterproof barrier whilst at the same time allowing the structure to breathe normally by permitting the transmission of vapour.

- Resists fungus and algae: Its special formulation helps to eliminate growth of fungus, algae, moss, mildew etc. on surface. It is also resistant to the acidic reaction of plaster like salt petre.

- Abrasion Resistant: Its tough yet flexible film is highly scrub and abrasion resistant. It can withstand high velocity winds.

- Economical / Durable: Its long service life and dual benefits of waterproofing and decorative finish and minimal maintenance makes it more cost effective than conventional paints

- Attractive finish: SB – 65 has a matt finish and is available in more than 60 shades.

PREPARATION

Wire brush and clean all foreign matter such as dirt, grease, laitence, mortar droppings, release agents, efflorescence and loose and flaking materials.

Washing the surface with detergent and water would be an added advantage.

All large voids or hollow portions must be removed and replastered locally with Chemistik Polymer Modified Repair Plaster.

Larger cracks or non moving cracks must be filled with our Acrylic Sealant, hairline cracks will be covered with the high build up of the coating.

Existing coatings or paint finishes must be prepared as above and the surface must be primed with AC 10 to prov idea good bond for the coating.

Surfaces to be treated must be sound, firm, clean, dry and fully cured prior to application. New surfaces to be cured for 28 days.

Ambient temperatures should not be below 5° or above 50°C.

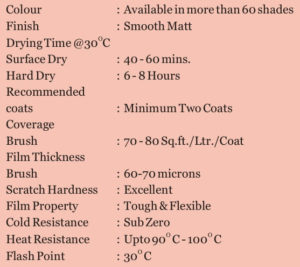

PRODUCT DATA

SB - 65