Kool Kote HF – 20 (Heat Reflective Coating)

PRODUCT DESCRIPTION

Kool Kote HF-20 contains highest quality of Pure Acrylic Resins combined with insulating and reflective fillers. It is a bright white elastomeric coating having high reflectivity to sun’s rays, hence keeping interiors cool during hot summer months. It is suitable for use on all types of horizontal and vertical surfaces. Being water base it is an ecofriendly coating.

METHOD OF APPLICATION

No primer required unless otherwise recommended for areas which cannot be prepared. In which case Prime-N-Seal primer tobe used.

Kool Kote HF-20 can be applied by brush or roller.

Apply first coat on prepared surface. Apply second coat within 8 hours at right angles of the first coat. Inter-coating interval should not be more than 8 hours.

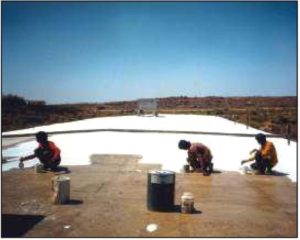

Finishing Kool Kote HF-20 should simultaneously be applied to all openings, protrusions, outlets, parapet walls, couplings, gutter valleys and expansion joints forming a good seamless, watertight finish. Treated surface should be allowed to curefor minimum 72 hours.

PRECAUTIONS

The surface to be treated should be clean and firm.

Do not apply on fresh concrete. Apply only after 28 days of curing.

Do not commence application when rain seems imminent.

Ambient temperatures shall not be below 5°C and more than 45°C. Avoid working during afternoons when temperatures are maximum. Do not apply during inclement weather or when rain appears imminent.

PACKING

1,4,20 Ltrs.

Centigrade Degrees

28° 31° 38° 40° 50° 55° 60° 65° 70° 7°81° 88° 95°

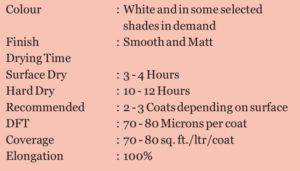

PRODUCT DATA

Kool Kote HF - 20

APPLICATIONS

As a reflective waterproof coating it can be applied on alltypes of masonry surfaces like external walls of buildings, parapets, chajas. All kinds of roofs, flat, sloping, inverted or even domes, steeples etc. it can also be applied on industrial roofs of GI, AC Sheets etc.

ADVANTAGES

- Reflects upto 60% of sun’s rays

- Keeps interiors cool-lesser energy costs Greatly reduces thermal load on surface Waterproofs masonry surfaces

- Good adhesion to almost all surfaces like concrete, wood, metal A.C. Sheets etc …

- Elastomeric can withstand building movements.

- High temperature resistance will not crack, peel or spall.

- Prevents growth of fungus, algae, mildew etc.

- Single component easy to use.

PREPARATION

Clean all foreign matter such as dirt, dust, grease, laitance, mortar droppings, loose and flaking materials. Moss and fungus must be removed using suitable fungicide solution or bleach or dilute HCL solution, thereafter wash thoroughly.

Necessary repairs to defects must be carried out prior to coating like crazed unstable or hollow surfaces, major cracks, any protrusion, outlets, construction joints etc. For cracks andjoints use our Crackseal Caulking Compound.

All surfaces to be treated must be properly prepared, sound clean, dry and fully cured and ready. New concrete to be cured thoroughly for 28 days prior to coating.

CLEANING OF TOOLS

Clean the tools, brush immediately with water.

STORAGE

Store in a cool, dry place away from direct sunlight.

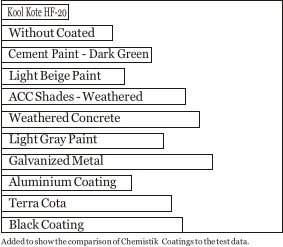

"BACK SIDE" SURFACE TEMPERATURES OF VARIOUS COLOURS

Condition: Khopoli (Outside Mumbai, Month of April-May, Ambient Temperature of 36°C, Clear sky- Time 2 p.m.

AC Sheets surface temperature without any coating was 55°C

SYSTEM

Tests were conducted to determine the effect of colours on the temperature of KOOL KOTE System when applied over cement panels. The above graph shows the difference between coloured coatings and other materials when exposed to sunlight. Ambient temperature above 38°C will result in even hotter surface temperature than those measured from the above graph. Itmay be seen that even light coloured coatings raise the temperature some what. Shiny aluminium coating reflects sunlight very well although not aswell aswhite coating.