Micro Concrete MC – 500 (Free Flowing Micro Concrete)

PRODUCT DESCRIPTION

Chemistik Micro Concrete MC – 500 Free Flowing Micro Concrete is a one component prepacked factory made micro concrete suitable for repairs to all kinds of concrete structures. It is developed and so formulated can be used to reinstate large sections of concrete or recommended to be used where access is difficult or complex reinforcements do not allow the use of conventional materials or methods. It is based on Portland cement graded fillers and additives which control shrinkage and reduce water demand and facilitate quick and easy working with controlled quality.

APPLICATIONS

This ready to use micro concrete enhances quality of work with its consistent quality which completely eliminates human errors of on site mixing. It can be used to repair large sections of damaged/spalled concrete, making good honeycombs in new concrete. Repairing of structural beams and columns. Repairing defects in Railway sleepers, RCC Hume pipes etc.

METHOD OF APPLICATION

This ready made micro concrete is difficult to mix by hand. Use a mixing vessel. Pour clean water into the vessel at 3.3 litre / per 25 kg bag. Add the micro concrete into it slowly under constant stirring conditions until lump free until a homogenous mix is attained Use a slow speed stirrer only. Where larger quantities are needed a mixer is required Pour immediately to get maximum flow properties. It is not recommended to mix part bag at a time. Once placing of micro concrete is complete and form work removed it is necessary to cure the area by keeping it under wet condition for curing as usual.

PRECAUTIONS

Storage conditions are very important to extend shelf life to 6 months • Do not split pack • For mixing add water exactly as advised • Pour once ready and moist cure as usual.

PACKING

25 Kgs. Poly lined bags.

ADVANTAGES

⦁ No compaction required

⦁ Very low permeability

⦁ Chloride free.

⦁ Excellent bond to concrete surfaces.

⦁ Can be pumped.

⦁ High early strength.

⦁ Reduces shrinkage.

⦁ Repairs upto 200 mm at onetime.

PREPARATION

Surfacepreparation is essentially important prior to application of Chemistik Micro Concrete MC – 500. After breaking the damaged area, remove all dust, dirt, gravel etc. wash and clean the area. Any or all exposed reinforcement which may show signs of corrosion must be fully cleaned of must and should be immediately coated with our Epoxy Tack coat for protection. It is necessary that all form work should be in place prior to pouring of the material. For additional bond or porous surface a second coat of epoxy may be necessary to be applied and repair to start while it is tacky.

CLEANING OF TOOLS

Wash all hands, tools and containers etc. with clean water immediately after use.

STORAGE

Store in a cool dry place away from water or humid conditions.

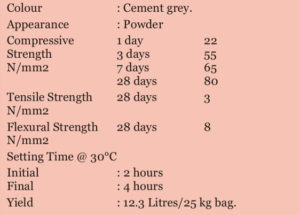

PRODUCT DATA

MICRO CONCRETE MC - 500