Epoxy Mortar SL – 1 / Epoxy Mortar TC – 2

PRODUCT DESCRIPTION

Chemistik Epoxy Mortar is a ready to use, solvent free, two pack system available in two types, mainly, (a) Self-levelling, pourable, consistency mortar no. SL – 1 : for floor toppings, cavity fillings, beddings. (2) Trowellable consistency type no. TC – 2 : for vertical surfaces, floor patch, foundations etc.

APPLICATIONS

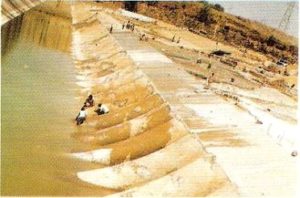

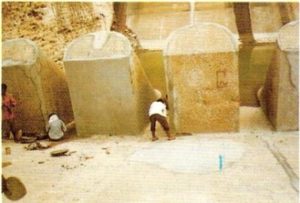

Bedding bridge pads or steel bridge bearings. Repairing vertical honeycomb R.C.C. concrete. Fixing bolt pockets. Fixing machinery foundations having heavy vibrations e.g. textile looms, rubber mills, turbines, generators etc. Fixing marble facing in vertical concrete for building facade. Repairing cavitations in dams, particularly buckets and spillways. Repairing factory floor having heavy industrial traffic and abuse of trolleys. Repairing concrete posts, tanks, pipes, roads, airport runways, aqueducts. Bedding acid proof tiles in chemical plant. Chemical and solvent resistant dustless floor topping for chemical and fertilizer factories, acid pickling tanks and floorings.

METHOD OF APPLICATION

Pour the mix on the prepared surface and level it with the trowel or putty knife depending on the type of mortar i.e. SL – 1 or TC – 2. For a good finish, dip the trowel in pine-oil or mineral turpentine or our EP THIN – 200. Finish by trowelling in one direction only. Make sure no air is trapped during pouring and finishing.

Trowel smoothly as described above by dipping the trowel in solvent etc.

PRECAUTIONS

The success of the adhesion of our mortar to the base depends on the meticulous cleaning of the surface. At first glance, the concrete surface might appear clean but invariably the old surface is crumbled, oily and greasy. It is therefore, imperative that the cleaning operation, though tedious is of paramount importance and should be done under strict supervision. While on most surfaces, epoxy mortar can be applied directly to give good adhesion, certain problem surfaces, like very old, corroded concrete may require a primer or a tack coat prior to the application of mortar for satisfactory bonding. A separate bulletin on EP TAC – 303 is furnished on request.

As with all materials of this type, work with adequate ventilation and take care to avoid excessive contact of the compound with the skin or splashes entering the eyes. Protect hands by wearing gloves or with the correct barrier creams. Contamination of the skin should be followed by cleaning the affected area with a suitable cleaning cream capable of removing synthetic resins from the skin followed by thoroughly washing with soap and water.

Do not attempt to split packs.

Do not store below 5°C.

Do not apply on fresh concrete.

PACKING

Pre-packed unit pair of 5 Kgs. available.

ADVANTAGES

Five times stronger than concrete. Resists acids and corrosive chemicals. Superior impact and abrasion resistant. Won’t crack, spell, chip or dust. Cures in 24 hours. Pre-packed pair in unit pack. May be applied on damp surfaces. Excellent adhesion to exposed steel reinforcement.

PREPARATION

The base must be clean, free of oil, grease and loose particles or dust. There are two methods of cleaning the base surface :-

1. Mechanical cleaning : Remove dust, loose particles etc. by sand blasting or wire brushing.

(a) Remove grease, oil etc. by washing with detergent and flush with water or

(b) Cleaning with Tri-Chloroethylene (solvent) Allow to dry the base.

2. Chemical cleaning : (a) Etch the base surface with commercial Hydrochloric acid and water in the ratio 1:2 by volume. Allow to stand on base for 20 to 30 minutes.

(b) Rinse with water containing dilute ammonia solution (1 part ammonia with 7 parts water).

(c) Flush and rinse with hot water. Allow to dry.

(d) Apply primer coat of EP-TAC 303 In case of freshly laid concrete allow 28 days to cure before applying the mortar.

The mortar consists of pre-weighted quantity of resin and hardener supplied separately in each container which comprises a pair. First, stir the resin container. Empty all the contents of the hardener into the resin container and mix thoroughly. A stirring device or an electrical mixture should be used for homogeneous mixing when large batch mix of 5 kg. is to be prepared. Avoid air-entrapment during mixing operation. Do not mix large quantities at a time as the pot life of the mix is limited.

CLEANING OF TOOLS

Use cleaning solvents immediately after use. Our EP THIN – 200 is recommended for smooth trowel finish and cleaning of tools.

STORAGE

Store in a cool, dry place away from direct sunlight.

PRODUCT DATA

EPOXY MORTAR SL - 1 / EPOXY MORTAR TC - 2

| SL-1 TC-2 | |

| Colour | : Grey Grey |

| Density | : 1800 Kg / M3 1900 Kg / M3 |

| Mixing Ratio Resin Hardener | : 90 : 10 By wt 93 : 7 By wt. |

| Compressive | : 900 Kg / cm2 1200 Kg / cm2 |

| Strength Drying time | : 30° C |

| Surface dry | : 1 to 1 1/2 hrs. 1 to 1 1/2 hrs |

| Hard dry | : 3 to 4 hrs. 3 to 4 hrs |

| Shrinkage | : About 0.5% About 0.5% |

| Flexural Strength | : 102 Kg / cm2 244 kg / cm2 |

| after 24 hrs. Scratch hardness | : Very High Abrasion Resistance |

| Temperature Resistance | : 140°C – 150°C 140°C – 150°C

It can withstand higher |

| Coverage/sq.ft per 1 mm

thickness per Kg. |

: 6 sq.ft 4 sq.ft. |