EP TAR – 202 (Coal Tar Epoxy)

PRODUCT DESCRIPTION

EP-TAR 202 is a solvent based two-component product evolved byblending of coal tar,epoxy resins with modified amine hardener and solvents.

APPLICATIONS

As an anti-corrosive coating material for concrete, plaster, iron and sleel, especially suitable for sewage works. For eg. coating sewage pipes, sewage treatment plants , decomposition silos etc. Furthermore, also applicable as protective corrosion inhibitor coating material in hydraulic steel constmction such as inhibitor coating for sluices, harbour installations, steel sheet pilling, bridges, bridge decks, cassions. Additionally, in ship-building as undercarriage coating.

Excellent cold insulation material in underground construction, for use as a protective coating on main ballast tanks and internal sea water tanks in submarines, outer bottoms of cathodically protected ships, internal and external surfaces of vessels, steel docks, deep tanks, crude oil tanks, potable water tanks etc. It resists the penetration of fouling organisms.

Due to the extremely low water absorption property of tar, combined with exceptional adhesion property of epoxy resins, the coal tar epoxy coating can be used for waterproofing underground concrete structures, internal coating of R.C.C tanks, swimming pools, reservoirs , irrigation aqueducts, sewage tanks, basement etc.

Oil and fuel resistant concrete floor covering car parks, ramps, industrial floors and ware houses.

METHOD OF APPLICATION

Chemistik EP-TAR 202 is a cold setting, two component product consisting of pre-weighted quantifies of basic resin and hardener. Mix both containers and stir thoroughly. It is important to completely empty the contents of tin containing hardener. Avoid air entrapments during the mixing operations.

Since the pot life of mixture is limited, mix only those quantifies which can be used within 6 to 8 hours. The coating must not be applied at temperature below 10°C and in humidity more than 85% as the setting process of applied material is a direct function of temperature. Inter coating of subsequent coats must be done while the previous coat is tacky or within 3/4 hours.

The coating must be applied by a clean dry brush, preferably nylon brush or a mop. Allow the coating to cure for at least 24 hours.

PRECAUTIONS

Avoid inhalation of solvent vapour and paint mist and avoid contact of liquid with skin and eyes. Provide proper ventilation when working with solvent borne coatings in confined spaces or stagnant air, provide respiratory, skin and eyes protection. Do not smoke in the vicinity and away from open flames, lights etc.

PACKING

Available in 4, 20 Ltrs.

ADVANTAGES

⦁ Excellent thermal and chemical properties.

⦁ High elasticity, ductility.

⦁ Totally waterproof, low water absorption.

⦁ High abrasion resistance.

⦁ Excellent resistance to sea water.

⦁ Resistant to mild acids, soda lyes, aliphatic hydrocarbons like petrol, diesel, oils etc.

⦁ Can be applied on damp surfaces.

⦁ Excellent adhesion to almost all materials/surfaces.

PREPARATION

If used on cement surfaces, it should be clean, firm, free from loose particles and mortar droppings as well as free from oil, fats and grease.

Steel surfaces should preferably be sand blasted to remove the skin and then mechanically scrubbed with suitable device to scrub the loose particles. Cleaning agents if used should be necessarily oil free types. Eventually mechanical roughening is required. Visible cracks in concrete if any shall be filled with our Epoxy mortar and allowed to dry.

Priming : On most of the surfaces, Coal Tar Epoxy can be applied directly to the surface which gives good adhesion, but when RCC/ Masonery underground tank are to be treated, especially surfaces exhibiting high absorbing capacity aprimer coat of our Chemistik EP Seal-100 is recommended which is to be applied first after which two coats of EP-TAR may be applied

Damp surfaces may require a primer coat of EP Seal – 100 prior to the application for satisfactory on bonding.

CLEANING OF TOOLS

Clean hands, tools etc. with EP THIN 200.

STORAGE

Store in a cool, dry place away from direct sunlight.

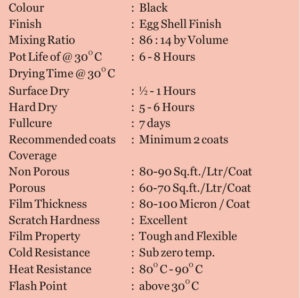

PRODUCT DATA

EP TAR - 202