EP Plus – 1000 SL (Self Levelling Epoxy Flooring)

PRODUCT DESCRIPTION

CHEMISTIK EP PLUS 1000 SL is a specially developed self levelling and self smoothing solvent free epoxy based heavy duty seamless floor coating where a very high build up is required to provide abrasion, chemical & impact resistance and a smooth table top finish to the existing concrete floor. It can be easily cleaned, is waterproof, dustproof and hardwearing surface, and has resistance to a variety of chemicals and solvents, oil, petrol, grease etc .. Maximum build up of upto 6 mm thickness can be layed on concrete floors.

APPLICATIONS

This self smoothing and self levelling heavy duty floor coating for concrete floors is highly recommended for use where high abrasion and chemical resistance is required for dust free and hygienic floors. It can be used very effectively in garages, light to medium industrial factories, hospitals, operation theatres, abattoirs, pharmaceuticals, food industries, electronic industries, warehouses, workshops and loading bays, exhibition and sports centres, aircraft hangars, battery rooms, fertiliser, chemical, engineering units etc. For cold storages and regions of extreme cold climates, ask for special grade PU 2000 SL.

METHOD OF APPLICATION

Once the surface is prepared and dried for 24 hours as above one to two coats of Chemistik Epoxy Sealer Coat EPS-100 to be liberally brushed on to the surface at an interval of 2 hours between each coat. Thereafter allow to cure for 2 – 3 hours thereafter. Mix the Resin & hardner of EP PLUS – 1000 SL thoroughly. After ascertaining the thickness required, suitable panels should be made (for larger areas) and the mixed material to be poured into each panel, spread out the material with a trowel or a flat blade, after which use a spiked special roller to remove entrapped air. In colder temperatures spiking may by required twice, the second after 2025 minutes. For large areas spreading + spiking can be done by wearing spiked shoes (do not wear flat shoes). Always finish edges when wet before initial cure. Now allow to cure.

PRECAUTIONS

All materials recommended are two components supplied as Resin + Hardener in pre weighted containers. Mixing of both Resin + Hardener thoroughly is of prime importance as otherwise it will directly affect the quality of material. Avoid direct inhalation and contact with skin and eyes. Provide proper ventilation when working in confined spaces or stagnant air. Do not smoke in the vicinity and away from openflames, lights etc.

STORAGE

Store in cool dry place away from direct sunlight. Do not mix and leave material overnight as it will cure and gel.

PACKING

Available in 5 Kgs., and 25 Kgs.

ADVANTAGES

- It provides a smooth industrial floor covering minor finishing defects of the concrete in one operation.

- It provides excellent resistance to dirt, dust and other environmental pollutants thus providing very hygienic conditions.

- It has excellent abrasion and impact resistance.

- It provides a flexible yet hardwearing surface.

- Excellent resistance to oil, petrol, a variety of chemicals and solvents.

- A very good aesthetic appearance. Easy to mix andlay, seamless coating.

- Can also be used in homes, offices etc., where tiling is not required or is not economical.

- Available in 10 Shades.

- Free from evaporating solvents hence very little odour. Can be safely used in enclosed or airconditioned areas.

- Its easy maintenance and hardwearing properties provides excellent protection to concrete increasing substantially the service life of concrete floor.

PREPARATION

All new concrete floors should be cured of minimum 28 days prior to coating. Old and existing surfaces should be clean firm and dry. Any pot holes, hollow or crumbly areas to be repaired with Chemistik Rapid Repair Morter laid to level of floor. All laitance, curing membranes, coatings, previous treatments to be removed completely. Very oily surfaces may require a chemical clean-up with florklin, and mild detergents and thereafter rinse thoroughly with clean water. For very oily or very old surfaces after necessary clean up operation, apply one to two coats of Epoxy Sealer Coat EP Seal-100 primer.

CLEANING OF TOOLS

Clean hands tools etc. with EP THIN – 200 only. The use of gloves and barrier creams is also recommended.

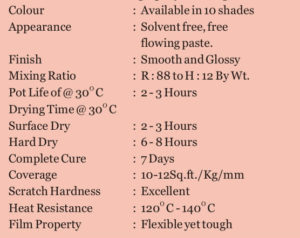

PRODUCT DATA

EP PLUS - 1000 SL (Self Levelling Epoxy Flooring)