EP GLOSS – 333 (Epoxy Enamel Paint)

PRODUCT DESCRIPTION

A two-component, high build glossy epoxy coating based on epoxy resin, EP GLOSS – 333 has excellent resistance to a wide range of chemicals, fresh and salt water, mineral oils, petrol, diesel etc.

Our epoxy compositions are available with both polyamide and amine adduct curing agent. These coatings have good exterior durability, improved adhesion and flexibility and good chemical resistance.

APPLICATIONS

As a protective coating where high chemical resistance is required, eg. internal lining of storage tank, urea prill towers, structural steel machinery and equipment, conveyor system, pipelines especially in fertilizer plants, chemical plants, petrochemical complexes, pharmaceuticals, dairies, offshore structures, abattoirs, electronic industries.

METHOD OF APPLICATION

Chemistik EP GLOSS 333 is supplied in two packs. Stir the individual component and mix them in specified proportion as given. Take only enough paint for the job in hand at at ime, since any paint left over will be cured and wasted.

If thinner is required, use our thinner EP THIN 200 only for thinning the paint and for cleaning the paint / spray tools etc.

Drying time indication depends upon the good ventilation and surface temperature and outside ambient temperature.

PRECAUTIONS

Avoid inhalation of solvent vapour and paint mist and avoid contact of liquid with skin and eyes. Provide proper ventilation when working with solvent borne coatings in confined spaces or stagnant air, provide respiratory, skin and eyes protection. Do not smoke in the vicinity and away from open flames,lights etc.

PACKING

1, 4, 20 Ltr.

ADVANTAGES

- Good adhesion and flexibility.

- Resistance to chemicals, salt water, alkalies etc.

- Resistance to mineral oils, petrol, diesel and other petroleum products.

- Resistance to different types of solvents and mild acids.

- Resistance to outdoor weathering agents.

- Can be used as an anti-corrosive decorative as well as protective coating

PREPARATION

The surface should be free from dust, oil, dirt, grease, rust, mill scales and loose particles of paint etc. Steel surface should preferably be sandblasted.

Use only where application on curing can proceed at a temperature above 10°C. Apply only on dry and clean surface with a temperature above dew point to avoid condensation. In confined spaces; provide adequat even tilation during application and drying. For application on metal surface a primer coat of Chemistik EP RO 400 or EPZ CH 401 is suggested after sand blasting. Primer selection depends on type of environment.

CLEANING OF TOOLS

Clean hands, tools etc. with EP THIN 200.

STORAGE

Storein a cool, dry place away from directsunlight.

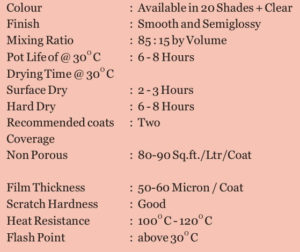

PRODUCT DATA

EP GLOSS - 333