Chemi Grout GP – 200 (Cementitious Non Shrink Grout)

PRODUCT DESCRIPTION

Chemistik Chemi Grout GP – 200 Cementitious Non Shrink Grout is a general purpose high strength cementitious grout in powder form when added with controlled quantity of water it becomes a free flowing grout or a stiff consistency material for vettical applications. Its formulation is based on Portland cement, graded fillers and additives which impart controlled expansion in a plastic state. By minimizing the amount of water a non-shrink mortar is produced for various uses in the construction industry.

APPLICATIONS

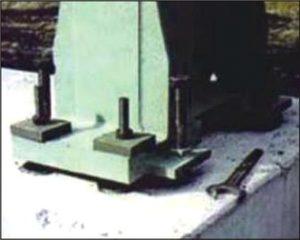

Ready to use grout when added with controlled quantity of water can achieve a free flowing or a paste type consistency for a variety of uses in the construction field like bedding in precast units in walls, roofs, slabs etc. Anchor bolts, machinery foundations, turbines, generators, filling holes of scaffolding supports, formwork, tiles etc.

METHOD OF APPLICATION

Chemi Grout GP – 200 to be added into gauging water slowly under constant stirring conditions until lump free and homogenous. For pourable consistency maximum 5.8 litres per 25 kg bag. For Plastic consistency maximum 4.0 litres per 25 kg bag. Once mix is ready for a free flowing grout it essential to ensure that pouring is a continuous process and it is not allowed to stop, the timing of pour must be regulated. The pouring must be from one side to avoid air entrappment. On completion all exposed areas should be thoroughly cured with continuous water or under we the assian cloth.

PRECAUTIONS

Storage conditions are very important to extend the shelf life to 6 months • Controlled quantity of water to be added as recommended • Wet curing is necessary • Mixing and pouring time should be monitored • Follow instructions carefully to gain maximum strength.

PACKING

25 Kgs. Poly lined bags.

ADVANTAGES

⦁ Non Shrink will not crack.

⦁ Non metallicand chloridefree.

⦁ Can beused up to 100mm at atime.

⦁ Readytousehence consistent controlledquality.

⦁ High bond strength toconcreteand steel.

⦁ High early compressive strength.

⦁ Minimum downtime.

⦁ Extremely low permeability.

PREPARATION

All areas where grout is to be placed should be free from foreign particles, loose or flaking materials and should be firm and damp. For mixing a electrical mixer should be used with a slow speed. The addition of water to the grout is of prime in portance should be as per recommendation only and the mixing time and pour should be monitored. This will ensure a good quality consistency, all formwork used should be leak proof. Areas to be treated should be presoaked for few hours, excess water must be removed, avoid entrappment of air which will reduce the contact area.

CLEANING OF TOOLS

Wash all hands, tools and containers etc. with clean water immediately after use.

STORAGE

Store in a cool dry place away from water or humid conditions.

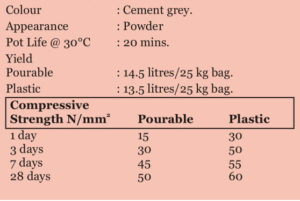

PRODUCT DATA

CHEMI GROUT GP - 200