Repair Plaster RP – 100 (Polymer Modified Repair Plaster)

PRODUCT DESCRIPTION

Chemistik Repair Plaster RP – 100 Polymer Modified Repair Plaster is a high quality polymer modified cement based ready mixed plaster mortar. It is a factory made mortar having a superior standard formulation based on Portland cement, graded fillers and additives which overcome the fluctuations and human errors of on site mixing. It can be used in spray application as well as manual. Ideal for quick repairing as well as levelling of undulations on the surface to attain a smooth levelled surface at all times.

APPLICATIONS

This ready to use repair plaster has a variety of uses for Repair as well as new work. It can be sprayed or used manually for plastering of brick walls or over precast slabs and blocks. Damaged concrete repairs or honey combs, Defect in concrete or masonry walls in thin coat for levelling and finishing, also can be used where light weight is required in air entrained structures like insulations, domes, steeples, foam concrete etc.

METHOD OF APPLICATION

To mix thoroughly one 25 kg bag of Chemistik Repair Plaster RP – 100 with 7 – 8 litres of clean water either by hand or with aid of electrical mixer for 3 – 5 minutes until a homogenous mix without any lump formation is achieved. It is now a trowellable consistency commence application and use within one hour. The application should be in layers each layer should not exceed more than 15 mm in thickness. Allow first coat to initially set and commence application of second coat, additional layers if required to be applied as above. Then allow the final coat to achieve initial set then trim, level, finish the surface with steel trowel to achieve desired finish and smoothness. For external sand finish plasters sponge the partially set mortar in circular movements until desired sand finished surface is attained.

PRECAUTIONS

Storage conditions are very important to extend the shelf life to 6 months • Moist curing of treated areas is required as usual • Do not add more water than recommended • Do not exceed thickness as recommended per coat.

PACKING

25 Kgs. Poly lined bags.

ADVANTAGES

⦁ Ready to use no mixing at site. Except water.

⦁ Controlled quality consistency.

⦁ Good adhesionto all concrete and masonry.

⦁ Water resistant.

⦁ Light Weight.

⦁ Good for internal or external use.

⦁ Good strength.

⦁ Clean: No mess of mixing various materials at site.

⦁ Economical as there is no wastage.

⦁ Can be used for guiniting work.

⦁ Good smooth finish.

⦁ Crack resistant.

⦁ Long open time and excellent workability.

PREPARATION

Remove all loose flaking materials expose the surface completely and free from laitance, grease, oils, mould release agents curing membranes, paints, coatings etc. It is recommended to wet the area to be repaired prior to use complete all plumbing or other works in the area. Fill all voids, corners etc. or any other defect in the surface prior to starting the work.

CLEANING OF TOOLS

Wash all hands, tools and containers etc. with clean water immediately after use.

STORAGE

Store in a cool dry place away from water or humid conditions.

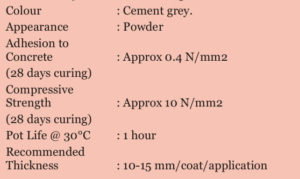

PRODUCT DATA

REPAIR PLASTER RP - 100